Soldering

Date:-19 sept 2017

Aim:-to learn to solder solderning

Requirements:-Blow lamp, pilier, soldering iron, hydrochloric acid, soldering rod, (lead,zinc,tin) tin sheet plate for making tin can copper cube glass flux.

procedure:-1) Take one glass and added hydrochloric acid.

2) Copper cubes is placed in the flame of blow lamp for heating.

3)Apply flux on the area to be soldered.

4) solder metal is kept on the area to be soldered. It is heated using red hot copper cube. solder metal. It solidifies to make perfect soldered joint

Observation:-1)Why flux is used for soldering.

2) Why acid is used to make flux

Conclusion:-1)a metal whose melting point is below the melting point of a job is used to join the job.

2) Soldering is used to solder job for less thikness

3) It can be done with less heat

4) Easy to do procedure.

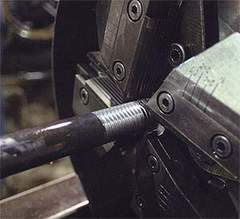

Images:-

Date:-19 sept 2017

Aim:-to learn to solder solderning

Requirements:-Blow lamp, pilier, soldering iron, hydrochloric acid, soldering rod, (lead,zinc,tin) tin sheet plate for making tin can copper cube glass flux.

procedure:-1) Take one glass and added hydrochloric acid.

2) Copper cubes is placed in the flame of blow lamp for heating.

3)Apply flux on the area to be soldered.

4) solder metal is kept on the area to be soldered. It is heated using red hot copper cube. solder metal. It solidifies to make perfect soldered joint

Observation:-1)Why flux is used for soldering.

2) Why acid is used to make flux

Conclusion:-1)a metal whose melting point is below the melting point of a job is used to join the job.

2) Soldering is used to solder job for less thikness

3) It can be done with less heat

4) Easy to do procedure.

Images:-